Making things, responding to what’s in front of you, thinking about your options, steps and consequences, and turning evolving ideas and data into instructions, illustrative stories and code for our rapidly progressing technologies are critical skills for teaching, research, science and art…

“I do not think there is any thrill that can go through the human heart like that felt by the inventor as he sees some creation of the brain unfolding to success.” –Nikola Tesla

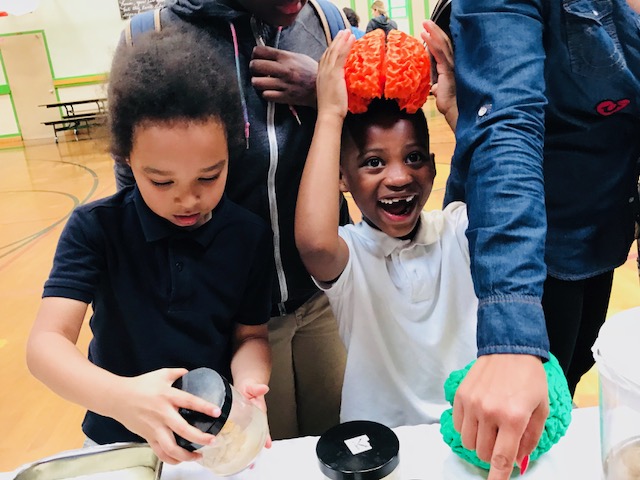

The act of building objects that reflect our physiology, demonstrate biological structure and capture essential aspects of neuroanatomy are also invaluable in the classroom, and in public settings where we engage audiences, provoke discussion and try physically grasping how things work…

To that end, we are indebted to a wealth of innovative makers, thinkers and coders at Portland State University, Oregon Health & Science University, Intel, the Portland 3D Printing Lab and the wonderfully welcoming Make + Think + Code at the Pacific Northwest College of Art…

We are especially intrigued and excited by 3D printing, a technology developed by Hideo Kodama, who first reported a “new method for automatic fabrication of a three‐dimensional plastic model” in 1981. He used a technique known as “photo-polymerization,” where exposure to UV light hardens a liquid material, layer by layer, into a 3D plastic model. It was an expensive technique, and also one requiring you to think about what you’re making, and code effectively to create…

An early 3D printer: the SLA-1 by Charles Hull, who created the first 3D printed machine part in in 1983. This stereolithography apparatus (SLA) extruded a photopolymer in layers that were subsequently “cured” by UV light

LEARN MORE: Automatic method for fabricating a three‐dimensional plastic model with photo‐hardening polymer

LEARN MORE: The History of 3D Printing: 3D Printing Technologies from the 80s to Today

LEARN MORE: Kodama, Hideo and Photopolymer 3D Printing

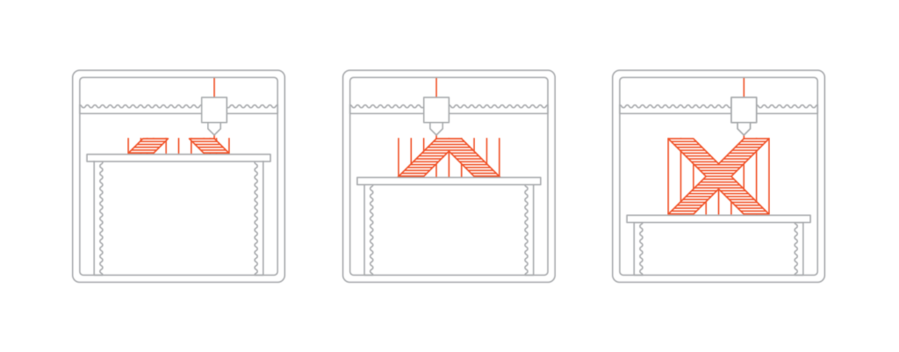

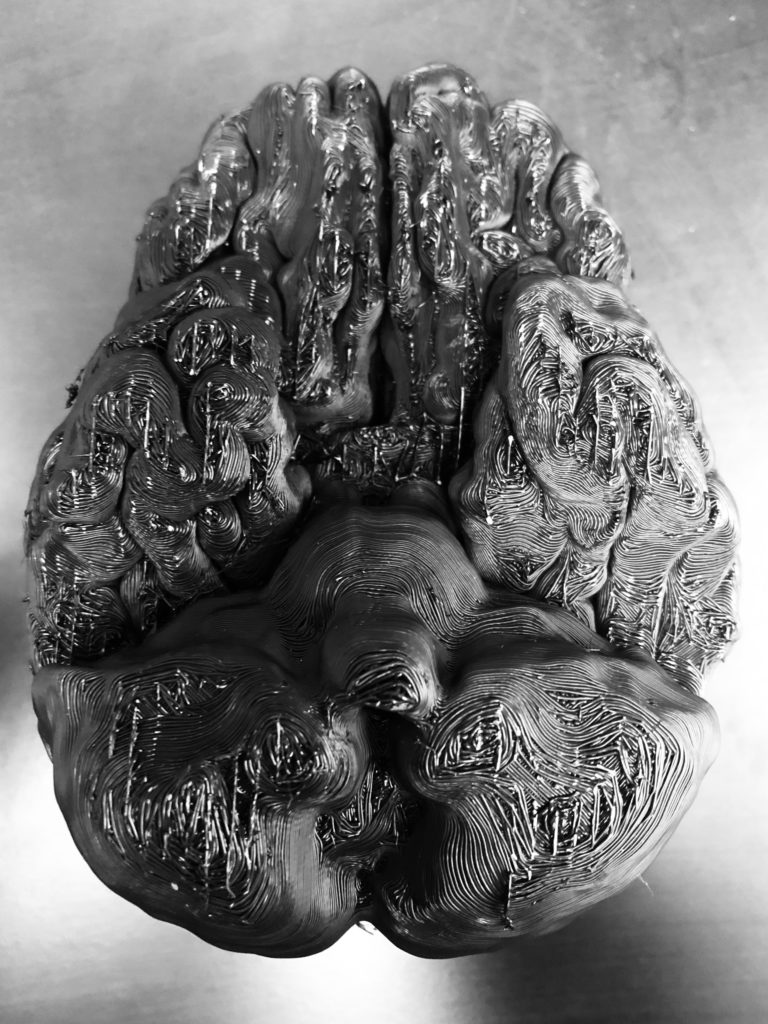

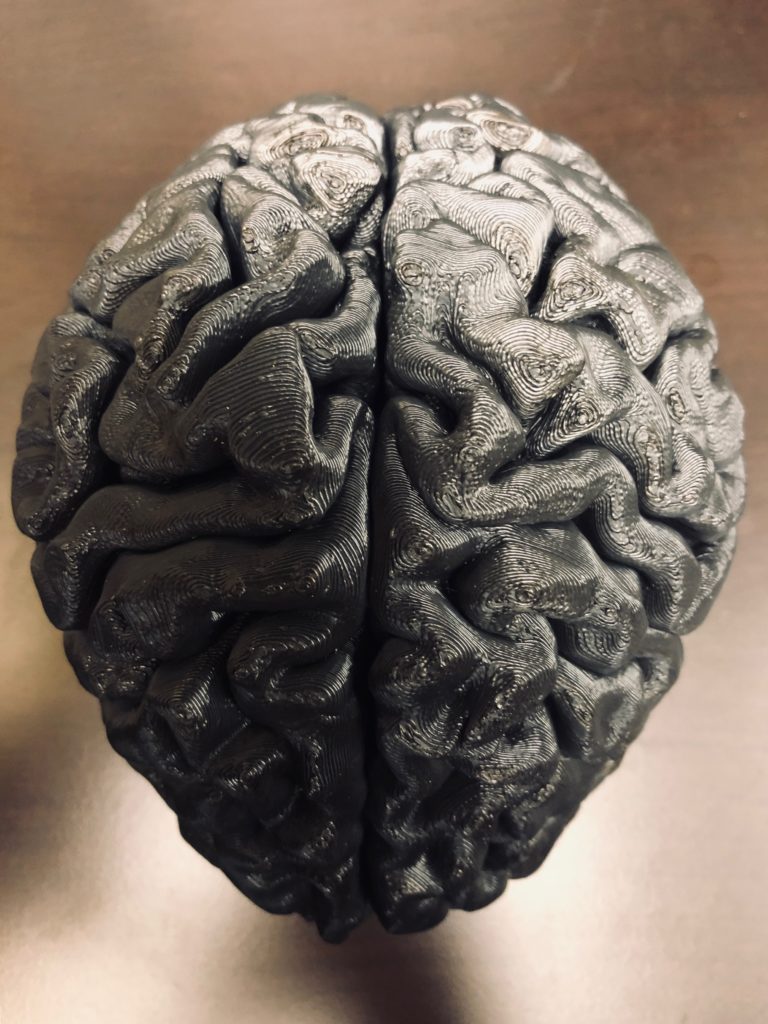

This technology has come a long way! Today, the cost is significantly lower, and newer additive processes are more common, including Fused Filament Fabrication (FFF) (or Fused Deposition Modeling (FDM)), where 3D objects are “printed” by a nozzle that extrudes melted thermoplastic filament layer by layer until the structure is complete!

Recyclable, compostable polyactic acid (PLA) filament, ready to be melted and deposited layer by layer…

LEARN MORE: Introduction to FDM 3D printing

LEARN MORE: Everything You Need To Know About Polylactic Acid (PLA)

LEARN MORE: IS RECYCLING PLA REALLY BETTER THAN COMPOSTING?

LEARN MORE: Development of the Improving Process for the 3D Printed Structure

LEARN MORE: How Much Does a 3D Printer Cost?

“And the good news is, is that new tools and technologies are making the building of things easier than ever. There is a democratization of manufacturing that is potentially available because of technology. Across our country, ordinary Americans are inventing incredible things…” –Barack Obama

LEARN MORE: Noggin @ White House Frontiers

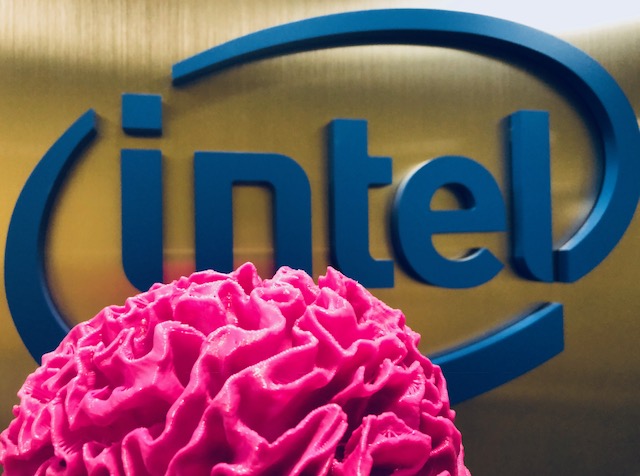

Shashi Jain, an entrepreneur, technologist, instructor and IoT Innovation Manager at Intel and the organizer of the Portland 3D Printing Lab, along with Miguel Higgins-Moy, a PSU engineering student and lab researcher at Uncorked Studios, and Nandini Ranganathan, Executive Director of the Make + Think + Code laboratory at PNCA, have all enthusiastically supported NW Noggin outreach through the creation of compelling, cerebral 3D prints…

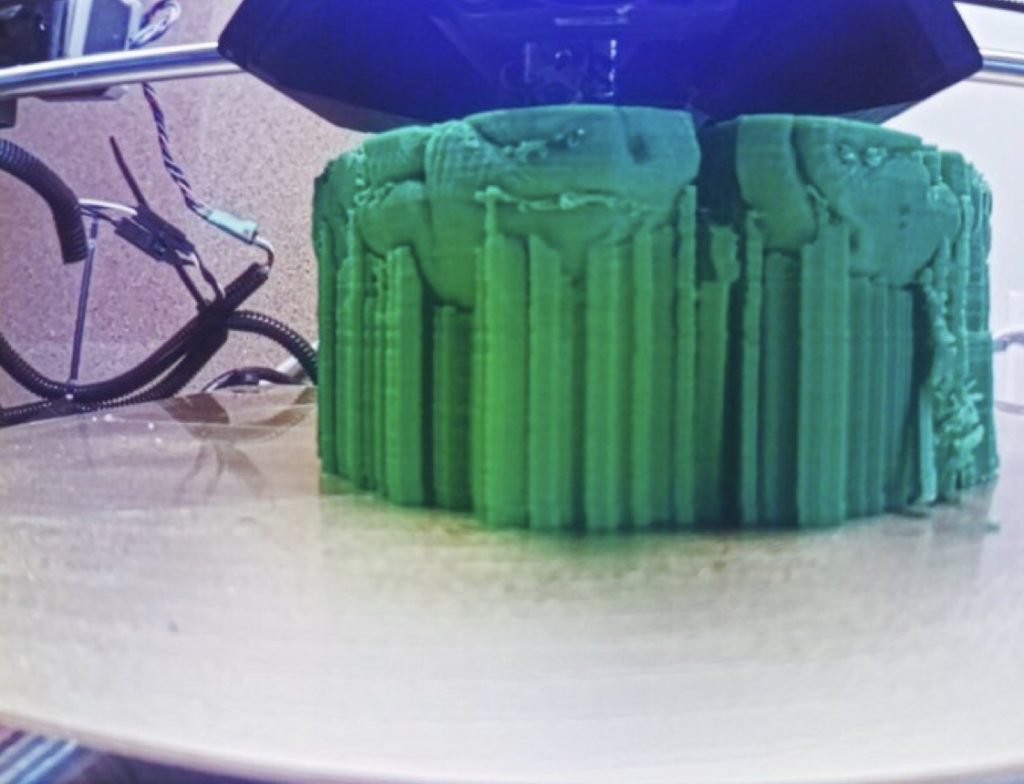

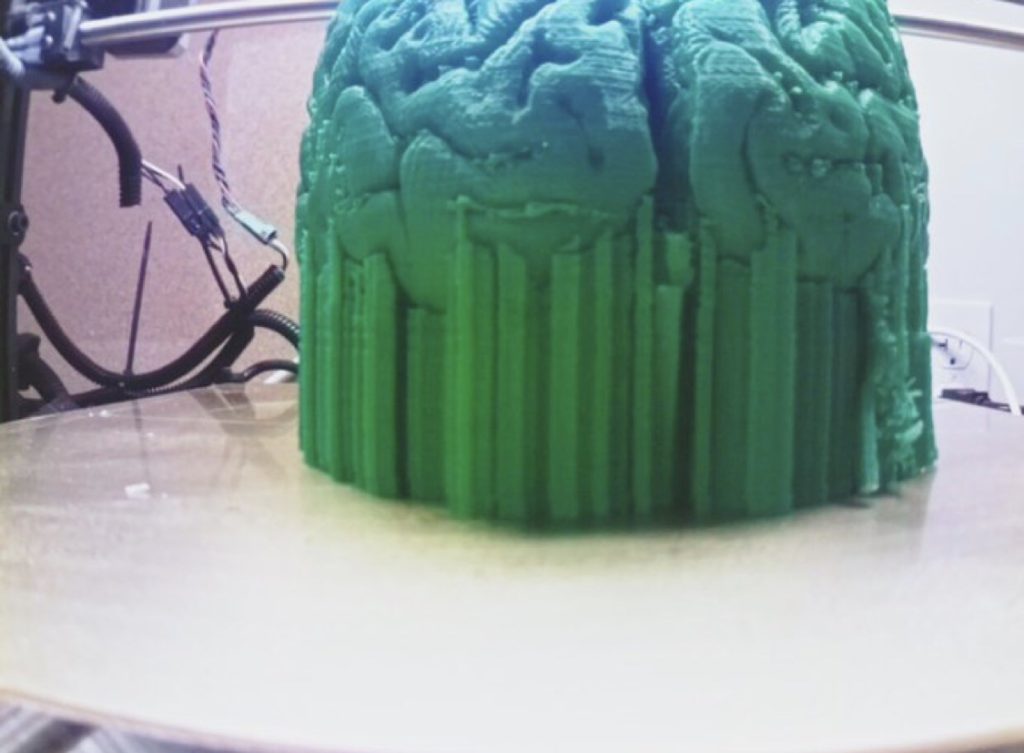

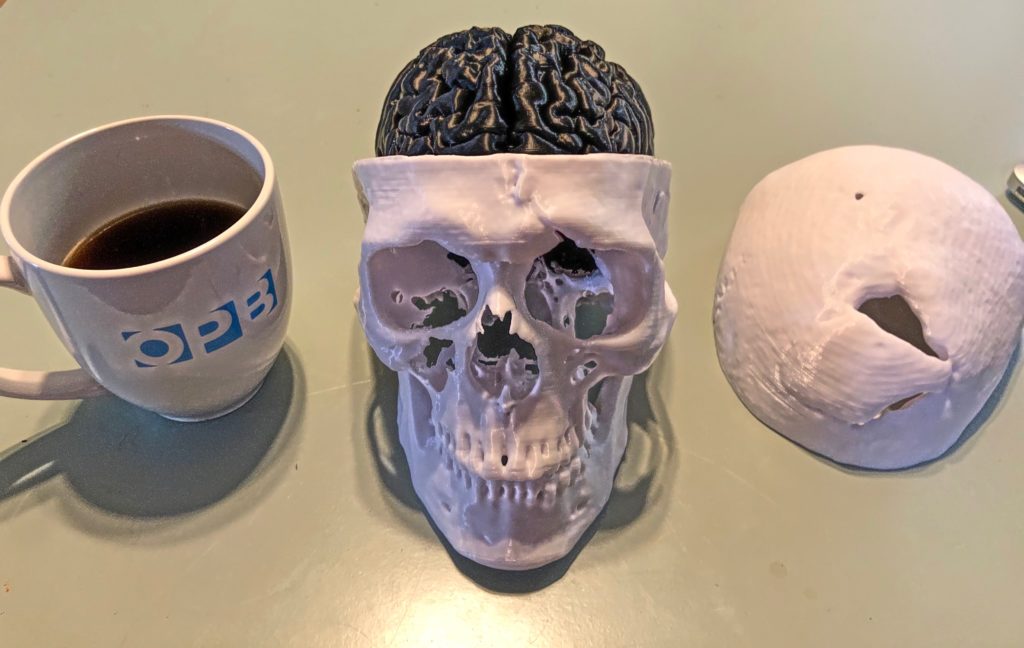

A human brain cortical surface print, in green PLA

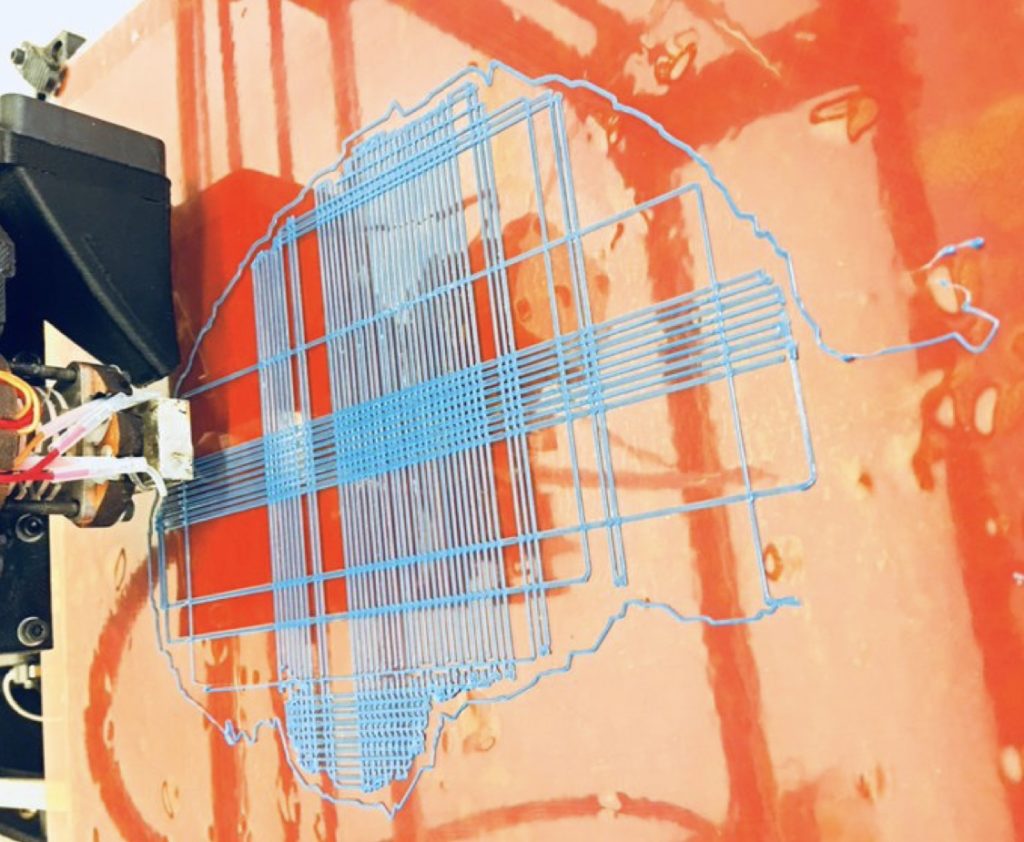

Binyam Nardos, a postdoctoral researcher and outreach co-coordinator for the Youth Engaged in Science (YES!) Program in the Fair Neuroimaging Lab at OHSU, provided the essential MRI structural imaging data (the code for printing an actual human brain) – and the result has been colorful and extraordinary!

A great benefit of this maker technology is the ability to represent multiple structural aspects of our neuroanatomy. For example, here below are two models (one in bright orange and one in bright pink PLA) of the underlying white matter (axonal connections) for that same green brain!

These two 3D print of axonal tracts (orange and pink) belong inside the other print (green)!

LEARN MORE: White matter in learning, cognition and psychiatric disorders

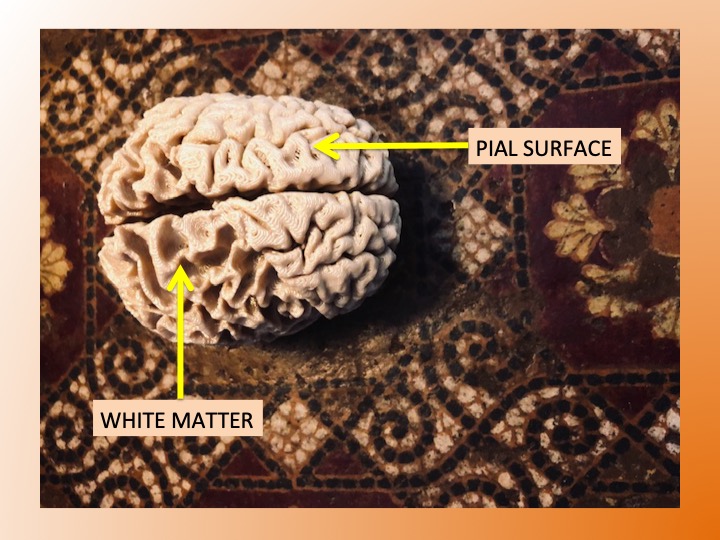

Binyam used a program called FreeSurfer to generate both that pial (the pia mater is the “soft mother” layer of the meninges that rests directly over the cortex) and white matter surfaces from MRI data. FreeSurfer can export surface files in .STL format, which can be read by a 3D printer.

LEARN MORE: FreeSurfer

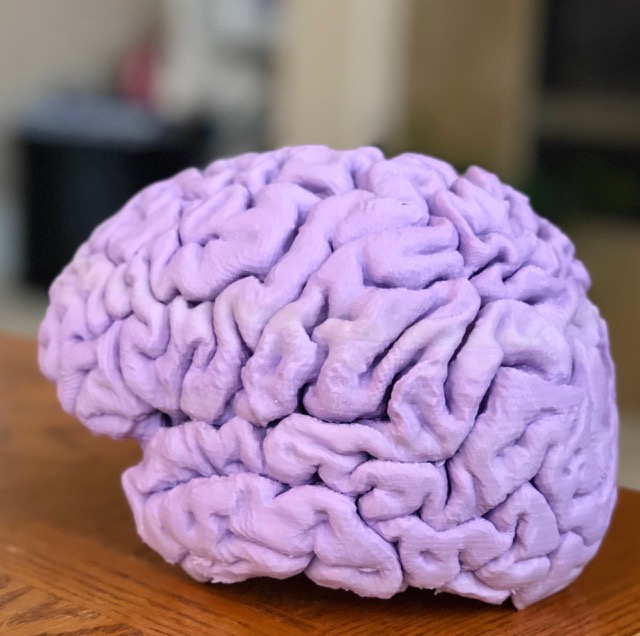

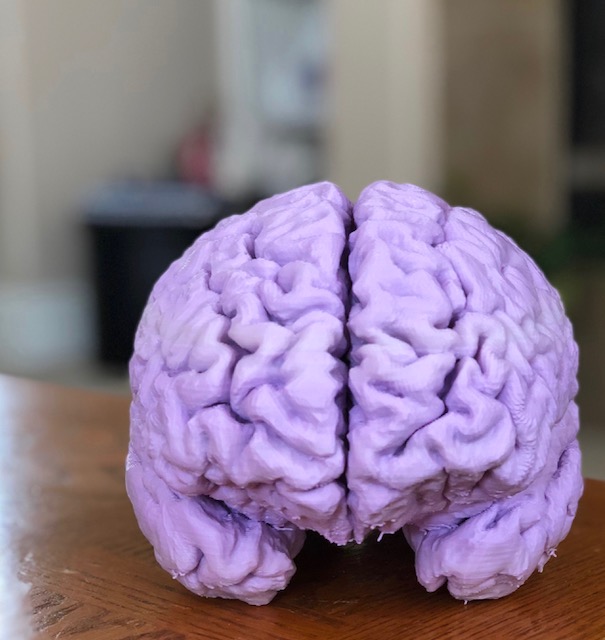

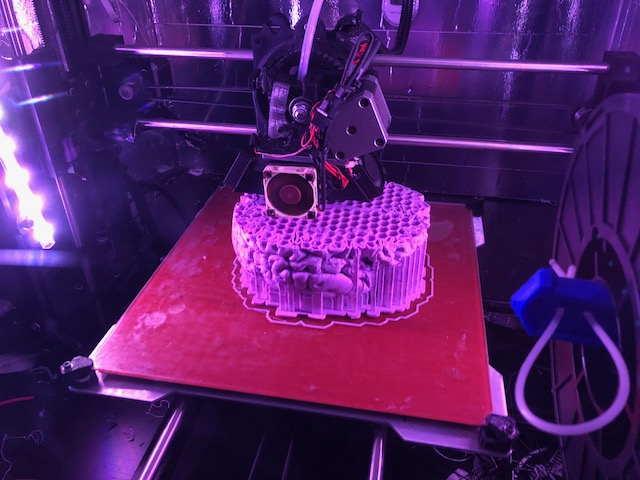

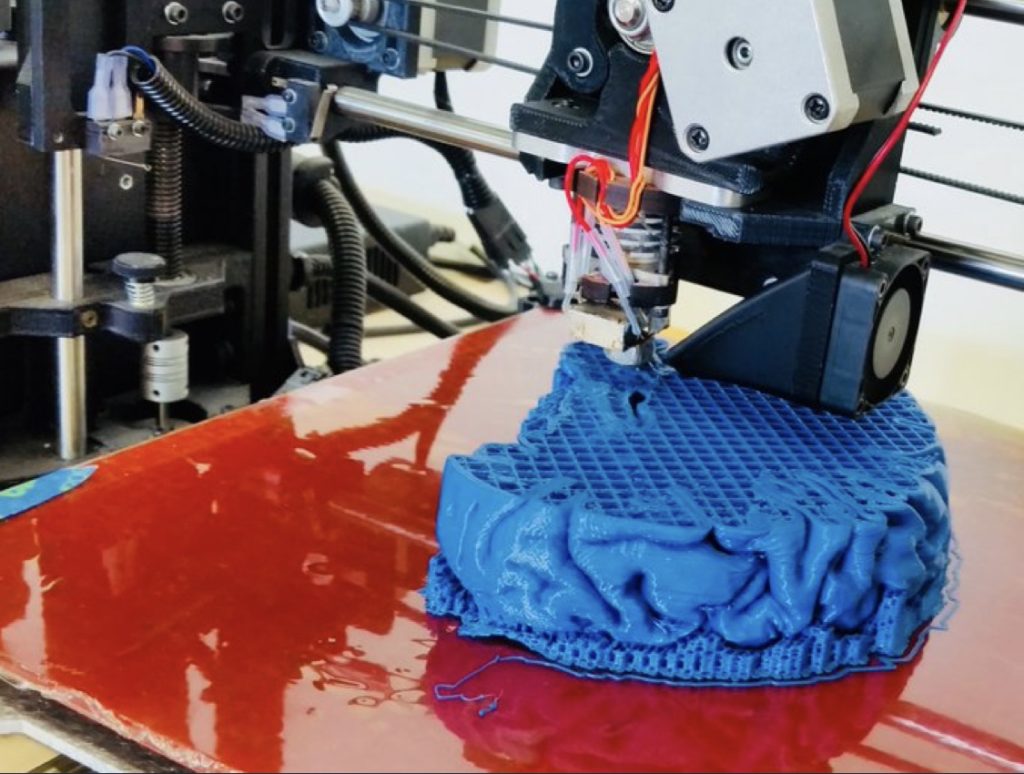

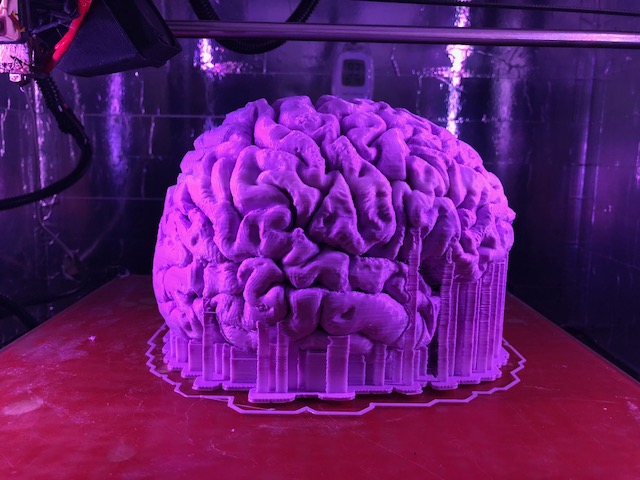

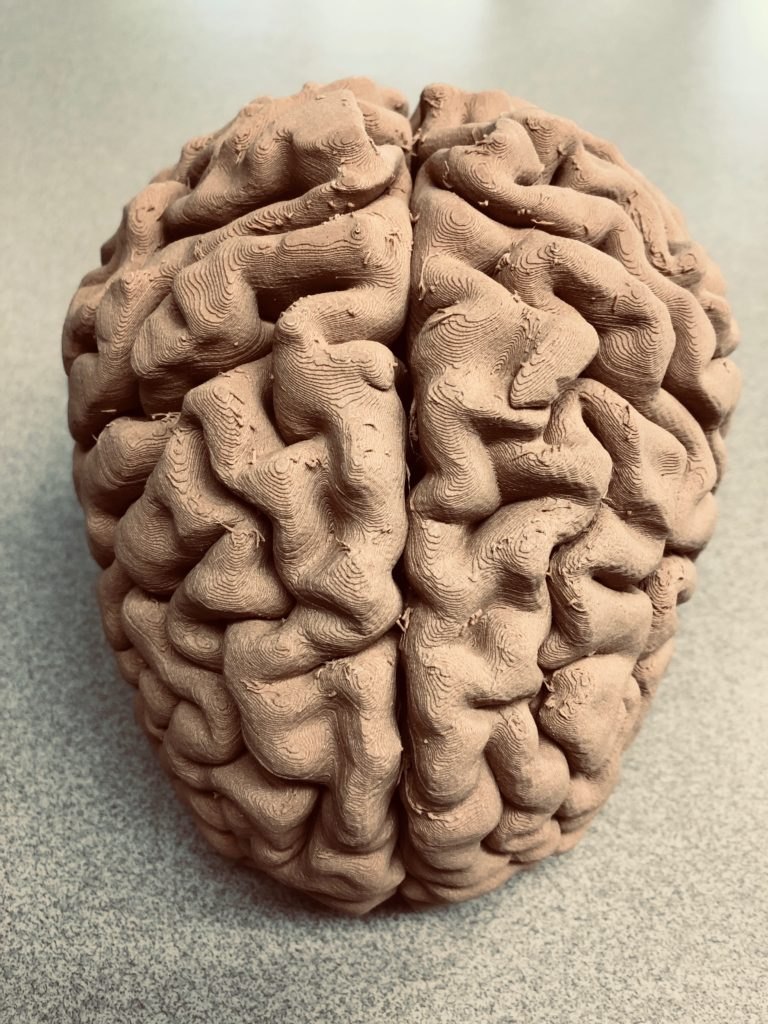

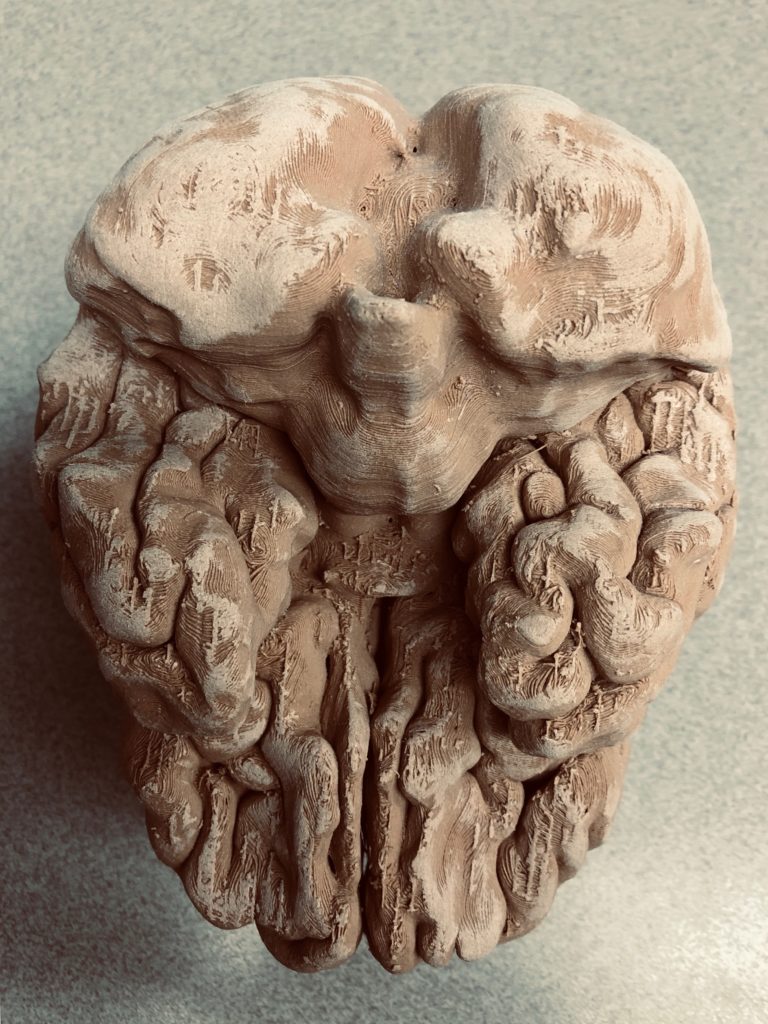

Here is the latest pial surface print, made by Shashi on a LulzBot TAZ 5 desktop 3D printer, using PLA filament in lilac…

The pia mater (“soft mother”) is a very thin transparent membrane that covers the cortical surface of the brain…

These prints take time, material and effort. The lilac brain weighs in at 820 grams (~1.8 pounds!), which is about a pound less than a real one. Printing alone took 37 hours (!!), and required subsequent scraping and clipping off excess PLA that had supported the developing structure during the process…

However, these models always attract student and public interest, and are tangible, graspable objects that help teach through visual inspection, direct touch and discussion about research related to the brain and behavior – and additional art projects that explore aspects of our fascinating neuroanatomy…

In fact, thanks to Shashi’s catalytic enthusiasm and the Native American Network at Intel, we are now planning to include 3D printed human and animal brains in outreach with tribal majority schools in Yamhill and Lincoln counties later this fall…

LEARN MORE: Teachers, Noggin, OPAHEC & Intel!

LEARN MORE: Synapses & Stories: Coyote, Grizzly & their Brains!

LEARN MORE: The Trickster in Bone

Thank you Shashi, Nandini and Miguel for making, thinking and coding in support!

More brains…Phineas Gage!

The rainbow brain!

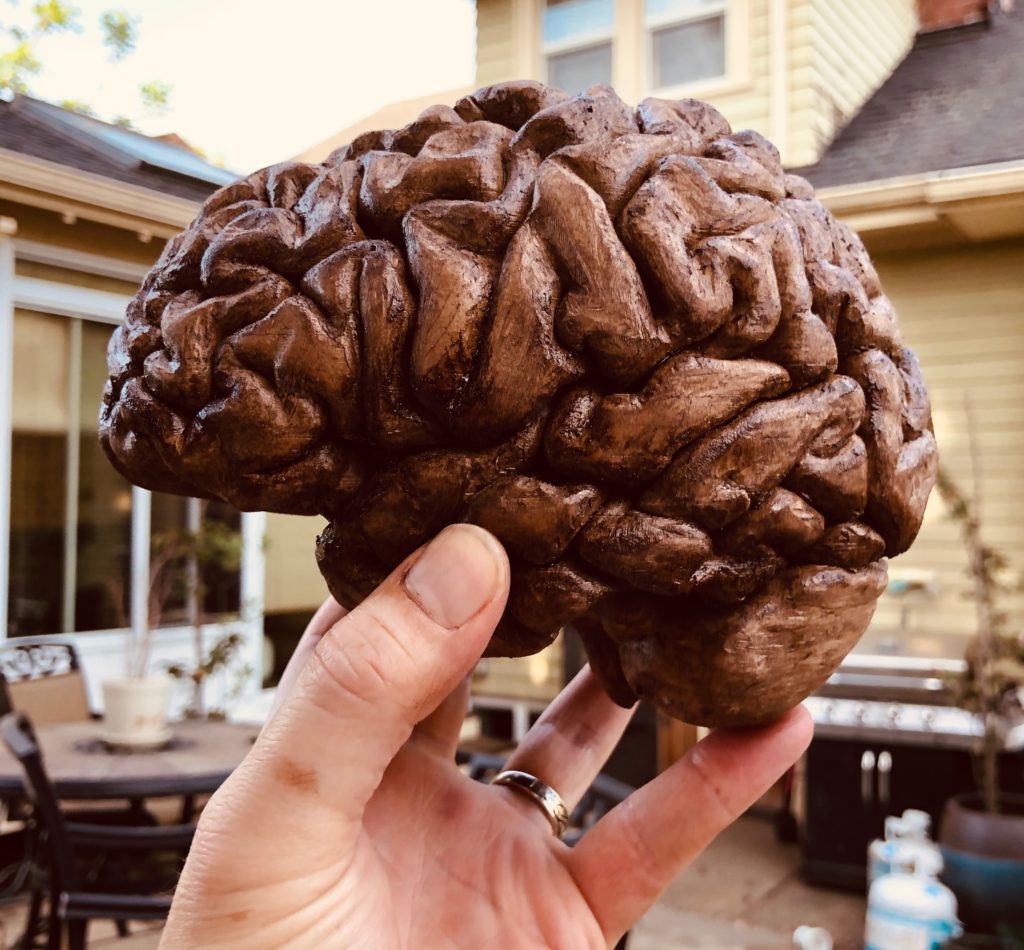

And now one made from Hatchbox 3D WOOD filament (wood particles plus PLA!)!!

Pre-sanding…

Sanding…

Sanding…

Staining..!